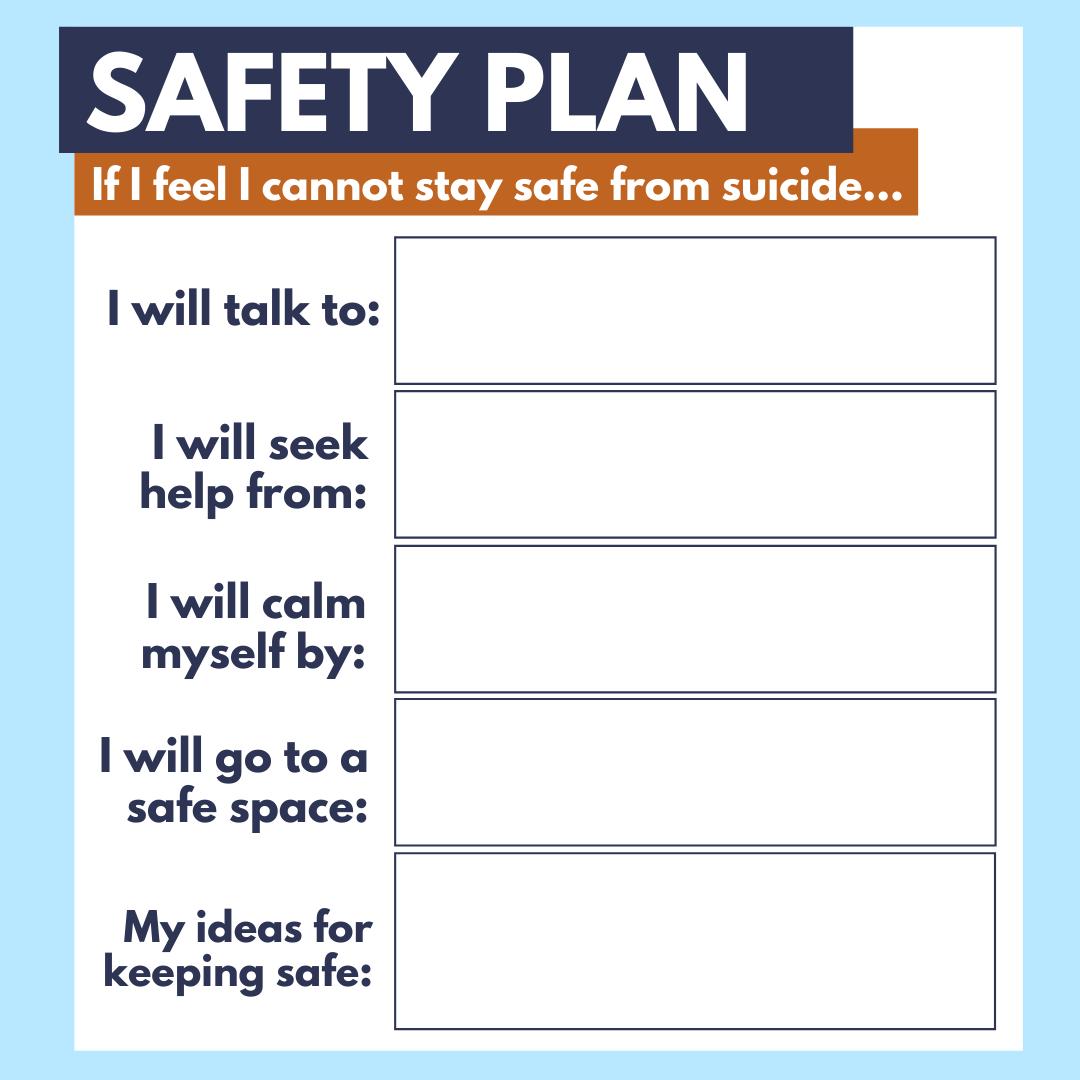

Department of Health and Social Services Safety Manual - Download the DHSS Safety Plan

Links

Documents

*Safety Plan Reviewed 05/04/2009

Table of Contents

2.0 Introduction to the Safety Program2.1 Overview2.2 Purpose and Expectations of Manual

3.0 Program Responsibilities3.1 Personnel

4.0 Safety Training and Communications4.1 Policy Standard4.2 Distribution of DHSS Written Safety Plan4.3 DHSS Central Safety Advisory Committee4.4 Safety Meetings—General4.5 Safety Meetings—Director Designee/ Site Supervisor4.6 New Employee Safety Orientation4.7 Training (Non-Office Workers)4.7.1 Director Designee/Site Supervisor4.7.2 Employee4.7.3 Training Lesson Plans4.7.6 Training Records Retention4.8 Safety Bulletin Boards

5.0 Accident and Incident Investigation and Reporting5.1 Objective and Definitions5.2 Accident Incident Investigation Procedures5.2.1 Death or Overnight Hospitalization

6.0 Blood-borne Pathogens6.1 Introduction6.2 Scope and Application6.3 Exposure Control Plan6.4 Roles and Responsibilities

7.0 Blood-borne Pathogens Exposure7.1 Purpose7.2 Scope7.3 Objective7.4 Program Requirements Exposure Determination

8.0 Interim Tuberculosis Exposure Control Plan8.1 Purpose8.2 Scope8.3 Objective8.4 Facts Concerning Tuberculosis8.5 Program Requirements

9.0 Safety and Health Inspections9.1 Annual Inspections9.2 OSHA Consultation Inspections9.3 OSHA Compliance Inspections9.3.1 Responsibilities of Division Compliance Inspections9.4 Hazard Classification Rating System

10.0Hazardous Material Management Program10.1Purpose10.2Scope10.3Objective10.4Definitions10.5Hazard Communication10.5.1Responsibilities10.5.2Program Requirements10.7Labeling Of Hazardous Material Containers

11.0Hearing Conservation Program11.1Purpose11.2Scope11.3Objective11.4Program Requirements

12.0Emergency Action Plans12.1Purpose12.2Scope12.3Objective12.4Program Requirements

GLOSSARY

APPENDIX A (SAFETY PRACTICES AND PROCEDURES)

APPENDIX B

2.0 Introduction to the Safety Program

2.1 Overview

This manual describes the safety standards that governs work to be performed at DHSS worksites.

At each location, every practicable effort will be made to sustain the integrity of DHSS's Health and Safety Program commensurate with maintaining the Commissioner's commitment to safety.

Section 3 details the specific safety safe work practice responsibilities of all DHSS employees. Our employees are expected to familiarize themselves with these safety responsibilities.

Accident and incident investigation is a very important part of any safety program because all available information and circumstances leading up to an accident or dangerous situation must be systematically evaluated to prevent recurrences. Section 5 describes the requirements of an accident /incident investigation.

Safety and health inspections are outlined in Section 9. This area describes how we recognize and report hazards.

Section 10 describes our Hazard Communication Management Program and outlines how we communicate these hazards to our employees.

Appendix A contains general safety standards and policies that serve as guidelines employees can follow to ensure safe work practices.

2.2Purpose and Expectations of Manual

The purpose of the Safety and Loss Prevention Manual is to provide:

- A practical system of policies, procedures and practices for the prevention and elimination of:

- Injuries and health hazards; and

- Negative environmental impacts.

- Sufficient information which will assist and enable all workers to work at minimal risk to themselves, fellow workers and the public.

- Line management with reliable information to successfully accomplish their health and safety obligations and responsibilities.

- A consistent approach to health and safety throughout the Department of Health and Social Services.

The expectations for the use of the Safety Plan are for employees to:

- Provide opportunities to know the health, safety and injury prevention information contained within the plan;

- Implement and comply with the health and safety practices and procedures;

- Provide input and feedback to improve the manual on an ongoing basis.

3.0Program Responsibilities

3.1Personnel

A. Safety Officer

- Administer the safety program for DHSS;

- Deal directly with division directors and safety committee representatives on safety issues;

- Help directors develop safety training programs for their divisions;

- Review work-related injuries.

- Investigate work-related fatalities and overnight hospitalization cases.

B. Central Safety Advisory Committee Members

- Assist in informing DHSS divisional employees about new and ongoing safety policies.

- Recommend new and revised safety rules and procedures for adoption by management.

- Promote accident prevention and safe job performance in their work areas.

- Evaluate and respond to employees’ safety suggestions and problems.

C. Division Directors

With the assistance of the Safety Officer will:

- Ensure that safety training is conducted for division employees.

- Ensure that safety rules and procedures are carried out in their division.

- Evaluate division managers' and supervisors' safety performance through regular performance evaluations.

- Prepare an annual training plan (non-office employees).

- Ensure that each location (with 10 or more employees) has an emergency action plan and that training is provided.

- Ensure that all employees who come in contact with hazardous materials as part of their employment are:

- provided necessary tools, equipment, training and information concerning safe work practices; and

- comply with safety practices, procedures and regulations pertaining to hazardous materials.

D. Employees

- Observe established safety policies and procedures.

- Notify supervisor of any unsafe conditions they discover.

- Use personal protective equipment where required.

- Attend required training or orientation to increase safety awareness.

- Promptly report all job-related injuries or illnesses to supervisor.

- Complete required workers' compensation forms within 24 hours of any work-related injury or illness.

- Familiarize themselves with the information in the safety plan and participate in site safety meetings.

- Provide input and feedback on the safety plan.

- Abide by all regulations relating to hazardous materials and participate in required training.

E. Director Designees/Site Supervisors

- Enforce the safety rules and procedures of this plan and any others that apply to their work.

- Ensure that safety training activities are carried out according to training plan designed by their division director.

- Promptly investigate all accidents and ensure corrective action is taken to eliminate cause of accidents.

- Perform annual safety inspection to identify workplace hazards or unsafe behavior and ensure corrective action is taken.

- Respond to employees' safety concerns and problems.

- Make sure all required accident forms are completed in a timely fashion.

- Keep records of safety meetings.

- Be responsible for ensuring that safety materials are presented, and be available toemployees.

- Discuss at safety meetings the following: unsafe acts or practices, recent injuries or near misses, first aid and emergency procedures, safety audits and pertinent scientific reports or findings.

- Conduct safety orientation with all new employees before they begin work and get Safety Orientation Checklist Form signed.

- Attend training on accident investigation, dealing with combative clients (if applicable) and hazard recognition skills.

- Develop and record a lesson plan for each safety training session.

- Maintain up-to-date records on health and safety training for each employee and retain for three years.

- Complete General Safety Inspection Form at least annually.

- Ensure the OSHA 300a Form is obtained from EEO Services, 240 Main Street, Juneau, AK ZIP, and that it is posted from February 1st through April 30th every year.

- Ensure that safety plans are available and up to date.

4.0Safety Training and Communications

4.1Policy Standard

The objective of the safety training and communication element is to provide all employees with consistent safety information, education, instruction and training sufficient for them to develop the awareness to protect themselves and others from injury.

4.2Distribution of DHSS Written Safety Plan

DHSS's written safety plan (i.e., safety manual) will be made available to every worksite location. This information will be kept in a location that is known and accessible to all workers.

4.3DHSS Central Safety Advisory Committee

A Central Safety Advisory Committee will be established for the following purposes:

- Promotion of accident prevention concepts to improve the department's overall safety performance;

- Reviewing accidents/incidents and developing plans to prevent recurrence;

- Presenting safety topics, literature, and/or videos which will enhance and maintain safety awareness;

- Providing a forum for participation, feedback and teamwork;

- Keeping current on safety issues;

- Establishing and maintaining a uniform and consistent approach to the DHSS safety and loss prevention program.

4.4Safety Meetings—General

The purpose of safety meetings is to acquaint employees with pertinent safety topics that relate to their work activities.

Safety meetings should be conducted within each division. Safety meetings provide an important communication link to each employee. Records of these meetings should be recorded on the DHSS Safety Meeting Lesson Plan.

Topics of discussion should pertain to safety items only. However, it would be reasonable for a supervisor to schedule the safety meeting before or after a regularly scheduled staff meeting.

4.5Safety Meetings—Director Designee/ Site Supervisor

The division director will be responsible for ensuring that safety meetings are conducted for all non-office related employees and will give guidance to director designees/site supervisors as to which topics will be presented. The director designee will then be responsible for ensuring that the material is presented to employees. He/she shall:

- Bring forward for discussion unsafe acts, practices or conditions that have been observed;

- Review recent injuries and near miss incidents. Discuss why they happened and what can be done;

- Encourage employee suggestions and discussion;

- Review first aid and emergency procedures;

- Use the results of safety audits as a source of discussion items;

- Share contents of recent scientific report or findings that relate to employee safety;

- Feel free to utilize written and audio visual aids. The Safety Officer in Juneau will collect and maintain a library of safety videos. These are intended to be loaned out to divisions per their needs. For more information call the Safety Officer at 465-4734.

4.6New Employee Safety Orientation

All newly hired employees need to receive a general safety orientation before they begin work. This orientation includes a review of applicable safety rules, practices and procedures. During this review items discussed will be marked on the Safety Orientation Checklist form. An example of this form can be found in Appendix B. The employee will then sign the checklist and it will become part of his personnel file. The director designee/site supervisor will be responsible for conducting the orientation.

The general safety orientation is as follows:

- Advise all personnel that working safely at all times is a condition of employment. It needs to be emphasized that DHSS is genuinely concerned about their safety.

- Review all on-site physical layout as it pertains to emergency assembly and evacuations.A review of on-site physical layout includes the identification of the following:

- emergency site exits

- emergency assembly areas (for emergency evacuation head counts)

- first aid facilities

- lunchrooms

- washrooms

- telephone locations

- interim storage areas

- roadway systems

- traffic logistics; and

- restricted areas

- Advise employees where safety handbooks and manuals are kept.

- Explain accident/incident reporting procedures.

- Identify the steps which must be taken.

- Recognize potential hazards;

- Eliminate potential hazards;

- Control potential hazards; and

- Minimize exposure to hazards.

- 6.The proper selection, care and use of protective equipment (if applicable).

- hard hats;

- safety glasses;

- safety footwear;

- eye protection/face shields;

- respiratory protection;

- hearing protection;

- gloves; and

- protective vests.

- The location of fire extinguishers and hoses.

- Reviewing the maintenance of tools, equipment and vehicles.

- Housekeeping standards for work areas.

- A review and demonstration of manual lifting procedures — Bend your knees!!

- A review of special mechanical lifting procedures (if applicable).

- A review of DHSS's Hazardous Communications Program and employees’ right to know about hazardous substances to which they may be exposed.

- Instructions for emergency response situations.

- Specific instructions or procedures for dealing with combative clients (if applicable).

4.7Training (Non-Office Workers)

4.7.1Director Designee/Site Supervisor

Director designees/ site supervisors are the key players in a successful safety program. They must promote the program directly to their employees. To accomplish this, the following training may be made available to them.

- Accident Investigation Skills

- Dealing with Combative Clients, (if applicable)

- Hazards Recognition Skills

4.7.2Employee

Safe work performance is a condition of employment within DHSS. Training requirements for non-office related employees will be determined and identified by division directors. The content of the training will address the specific hazards or needs relating to the employee's worksite. Director designees/site supervisors are responsible for presenting the material to their non-office designated employees

4.7.3Training Lesson Plans

Careful planning and organization is required to present effective safety training. In order to fulfill DOL-OSHA expectations for training, a lesson plan will be developed for each training session. The DHSS Safety Meeting Lesson Plan form can be used for recording lesson plans. An example of this form can be found in Appendix B. Examples of completed lesson plans for topics such as back safety, slips and falls and video terminal ergonomics can be obtained by calling the Safety Officer.

A lesson plan should serve as a blueprint for training. A good lesson plan incorporates the following:

- Presents material in proper order.

- Emphasizes material in relation to its importance.

- Keep classes focused and on schedule.

- Encourages trainee participation.

- Complies with OSHA expectations for safety training.

4.7.5Defensive Drivers Training

A sizable percentage of DHSS employees must operate either state owned, leased, rented or personally owned vehicles to conduct state business. Considering the volume of this activity along with the frequent adverse weather conditions found in Alaska, it is important that the department help upgrade the basic level of competence. Defensive drivers training is intended to give employees the knowledge and tools to be better drivers. The areas covered in this training include:

- Developing defensive driving skills;

- Split-second decision making;

- Backing-up;

- Keeping safe distances;

- Staying alert at intersections;

- Driving in poor weather conditions.

Division Directors are encouraged to provide within their training budget an opportunity for employees who must drive frequently on state business to attend a defense driving class.

4.7.6Training Records Retention

Up-to-date records must be kept of all health and safety training, including orientations for each employee. Training records must be retained for a minimum of three years. They should be readily available for review.

4.8Safety Bulletin Boards

A safety bulletin board will be displayed in each DHSS facility that has 10 or more employees to provide employees with a centralized location for the posting of safety related information.

The following considerations should be made for bulletin boards:

- Designate a specific bulletin board or portion of an existing board and reserved exclusively for safety material.

- Place in a spot where there is the greatest employee exposure (lunchroom, break room, central part of facility);

- Postings are arranged neatly;

- Remove Posters, safety committee minutes and other information that is outdated;

Director designees/site supervisors will be responsible for the upkeep of bulletin boards.

The following items are to be posted:

- OSHA 300a Summary (specifically during the period February 1st through April 31st);

- OSHA 2003 Poster (Safety and Health Protection on the Job);

- OSHA "It's Your Right to Know" Poster;

- Emergency Telephone Numbers 8"x11".

5.0 Accident and Incident Investigation and Reporting

When an employee is injured on the job the employee is to complete the DOL Report of Occupational Injury and Illness form (ROI) (07-6101) and give it to his or her supervisor who in turn will forward it to:

ROI@admin.state.ak.us by email

Or

Fax to:

The original form should be sent to:

Employee’s supervisor is required to complete the Supervisor's Accident Investigation Report form and send it accompanying the ROI.

These two forms may be downloaded from the Department of Administration Risk Management Web page. (See Forms) at Web site as follows:

http://www.state.ak.us/local/akpages/ADMIN/drm/forms.shtml

5.1Objective and Definitions

The objective of an accident/incident investigation is to determine the cause and to implement suitable corrective measures.

An investigation is a systematic process of examination, observation, and inquiry comprised of three parts including:

- Description of accident/incident;

- Cause of accident/incident (Why did it occur?);

- Recommendations.

After the cause of accident/incident has been determined, recommendations to prevent recurrence should be prepared.

Below are key definitions relating to accidents and injuries:

- Recordable Injury

- Any accident to an employee(s) that results in death or injury

- Any accident that results in a loss of consciousness, restriction of work or motion, transfer to another job, or medical treatment other than first aid

- First aid Injury

- Is an accident to employee that results in one time treatment of minor cuts, scratches, bums, etc., which do not ordinarily require medical care

- Subsequent observation of said injuries.

- Occupational Illness

- Is any abnormal condition or disorder caused by exposure to environmental factors that is associated with employment.

- Caused by inhalation, absorption, ingestion, or direct contact.

- Exposure incident

- Is a specific eye, mouth, other mucous membrane, non-intact skin, or contact with blood or other potentially infectious materials that result from the performance of an employee's duties.

5.2Accident Incident Investigation Procedures

5.2.1Death or Overnight Hospitalization

Accidents involving the death or overnight hospitalization of a DHSS employee must be taken with extreme concern. It is the supervisor’s responsibility to investigate and document all the circumstances related to employee accidents and take constructive action to prevent recurrences.

Immediately following an accident the supervisor must:

- CompletetheDOLReportofOccupationalInjuryandIllnessform(ROI) (07-6101) and email it to: ROI@admin.state.ak.us orEmployee ServicesDivision of PersonnelFax:(907) 465-5850Original form should be sent to: Employee ServicesDivision of Personnel240 Main Street, Suite 501 Juneau, Alaska99811It will also be necessary for the supervisor to complete the Supervisor's Accident Investigation Report form and send it accompanying the ROI.

- The Alaska Occupational Safety and Health Administration Statute 18.60.058(a) states that in the event of an employment accident, which is fatal to one or more employees or results in the overnight hospitalization of one or more employees, the employer must report the accident to the Division of Labor Standards and Safety no later than 8 hours after receipt of information that the accident occurred.In order to comply with Section 18.60.058 and avoid serious penalties, it is critical that death and overnight hospitalization cases be reported to the Alaska Department of Labor 907 (269-4940) immediately. This reporting requirement also applies to injuries where there has been a loss of consciousness. These accidents must also be reported to the DHSS Safety Officer.

5.2.2Recordable and First Aid Cases

The Supervisor must:

- Investigate the accident by talking with the injured employee and anyone else who may be able to offer information. If possible, go with the employee to the exact area where the injury occurred and ask him/her to describe how it happened. The questions, who, what, when, where, why and how can be used to establish baseline information. Ask more pointed questions that can help uncover the real causes of the incident. Once causation has been determined, look at ways the accident could have been prevented. Be willing to modify physical work locations, job procedures, protective equipment requirements or anything else that can help prevent recurrence.

- Complete the DOL Report of Occupational Injury and Illness form (02-921) and distribute. It will also be necessary to complete the Supervisor's Accident Investigation Report form (02-932) and distribute. A copy of the Supervisors Accident Investigation form should be forwarded to the Safety Officer in Juneau.

6.0Blood-borne Pathogens

6.1Introduction

Blood or certain other body fluids may contain pathogenic agents, that is, microorganisms that cause disease. Among those pathogens that may be present are Hepatitis B and C viruses (HBV or HCV) or human immunodeficiency virus (HIV), which causes AIDS. If an individual has blood exposure to broken or injured skin, mucous membranes of the eyes, nose, mouth, or by needle stick or other injection, there is the potential of infection with any possible pathogen that might be present. To minimize the risk of infection, information and training must be provided to those who will likely be exposed; Hepatitis B vaccination is offered; protective measures in the work environment are instituted; and exposures are reported to ensure that proper medical evaluation and treatment can be provided. It is especially important that employees with potential exposure understand and follow the principle of "Universal Precautions" as required in the Occupational Safety and Health Administration standard. "Universal Precautions" is the infection control approach in which all blood and body fluids are treated as if they are infected and the necessary precautions are taken.

6.2Scope and Application

State OSHA standards require a Blood-borne Pathogens Program for employees with job responsibilities which "reasonably expose" them to blood and certain other body fluids, unfixed human tissue or cell cultures. This program is intended to prevent infection with blood-borne pathogens. Under DHSS policy, the Blood-borne Pathogens Program applies to all individuals who may be exposed through department activities.

6.3Exposure Control Plan

Each department develops a written Exposure Control Plan indicating those job classifications and the tasks and procedures which involve potential exposure. The plan also includes an indication of the required engineering and work practice controls, personal protective equipment, housekeeping, labeling, training, and medical surveillance functions that will be instituted.

A. Training

Training must be provided initially at the time workers are assigned tasks involving exposure and annually thereafter. This training is provided by each division as needed with the support of the DHSS Safety Officer. Training content will include:

It is the responsibility of the supervisor to ensure that workers complete initial and annual training.

B. Medical Surveillance

6.4Roles and Responsibilities

A. Department Manager

B. Supervisor

C. Safety Officer

D. Individual

If you have questions relating to blood-borne pathogens please refer to your site specific Blood-borne Pathogens Exposure Control Plan at your facility.

7.0Blood-borne Pathogens Exposure

7.1Purpose

To outline responsibilities, establish procedures, guidelines and proper practices for dealing with occupational exposure to blood-borne pathogens.

7.2Scope

Applies to all DHSS employees who may come in contact with blood-borne pathogens during the course of their employment.

7.3Objective

To protect the health of DHSS employees who may be exposed to blood-borne pathogens by establishing work practice controls and providing education and training to reduce the risk of exposure.

7.4Program Requirements Exposure Determination

DHSS is required to determine which employees may have occupational exposure to blood or other potentially infectious materials. This determination is made in three categories: (l) job classifications in which all employees can be reasonably anticipated to have occupational exposure regardless of frequency of that exposure; (2) job classifications in which some employees have occupational ensure, again without regard to the frequency of that exposure and (3) those job classifications which do not have occupational exposure.

7.5Engineering and Work Practice Controls

A. Compliance with Engineering And Work Practice Controls

Unit or shift supervisors are responsible for enforcing the following engineering and work practice controls.

B. Universal Precautions

Universal precautions will be observed at each facility in order to prevent contact with blood or other potentially infectious materials. All blood or other potentially infectious materials will be considered infectious regardless of the perceived status of the source individual. Blood is the single most important source of HIV, HBV, and other blood-borne pathogens in the occupational setting. Infection control efforts for HIV, HBV, and other blood-borne pathogens must focus on preventing exposures to blood as well as on delivery of HBV immunizations* Universal precautions also apply to tissues and to the following fluids: cerebrospinal fluid, synovial fluid, pleural fluid, peritoneal fluid, pericardial fluid, semen, vaginal secretions and amniotic fluid. Exposure to these body fluids is exceedingly rare within DHSS work settings. Universal precautions do not apply to saliva (except in dental practice where mixture of saliva and blood is common).

C. Hand Washing

- Clinics where blood is drawn (ventipuncture, finger stick, heel stick, etc.), where patients are examined, dressings changed, or where potentially infected materials are collected should have an easily accessible sink supplied with warm running water, soap, and paper towels.

- If blood must be drawn or other activities are engaged in that may lead to exposure to blood or other potentially infectious materials and a sink and running water are not available, either an antiseptic hand cleanser must be available in conjunction with clean paper towels, or antiseptic towelettes must be available. The employee must use the antiseptic for temporary cleansing and then wash his/her hands as soon as possible at a sink once the task(s) involving potential occupational exposure is completed.

- Supervisors and program managers must ensure that employees wash their hands or use an antiseptic hand cleanser immediately or as soon as feasible after: (1) the removal of gloves or other personal protective equipment; and (2) finishing tasks in which an employee has been using an antiseptic towelette for temporary cleansing between exposures.

D. Work Practice Controls To Be Followed At All Times

- Needles and Sharps

- Contaminated needles and other contaminated sharps shall not be bent or recapped under any circumstances.

- Only disposable needles and sharps will be used. There will be no reprocessing of disposable equipment.

- Immediately after or as soon as possible after use, contaminated needles or sharps shall be placed into a sharps container which is puncture resistant, labeled or color coded as a biohazard, leak proof on the sides and bottom, and cleansable. Lids must be kept closed on sharps containers when not in active use and during transportation.

- Sharps containers will be replaced when they are three-quarters full to prevent overfilling of the container. Containers must be positioned or mounted in such a way that the opening into which sharps are to be placed is clearly visible.

E. Work Areas

- Eating, drinking, smoking, applying cosmetics or lip balm, and handling contact lenses are prohibited in work areas where there is a reasonable likelihood of occupational exposure. This includes any area where blood or other potentially infectious materials are collected, processed or tested.

- Food and drink shall not be kept in refrigerators, coolers, freezers or cabinets, or on shelves, counter tops or bench tops where blood or other potentially infectious materials are present or may be placed. Equipment such as refrigerators and coolers used for storage or transport of biological samples shall not be used for any other purpose.

- Blood Drawing, Blood Handling, and Specimen Collection

- Blood drawing and handling of blood or other potentially infectious materials shall occur in designated areas in each office, clinic, or other facility. If blood must be processed in large quantities ( as in the case of a population survey or disease outbreak), an area may be temporarily designated as a handling area for the collection or packaging of samples.

- Mouth palpating/suctioning of blood or other potentially infectious materials will not be done under any circumstances.

- Specimens of blood or other potentially infectious materials shall be placed in labeled containers that prevent leakage during collection, handling, processing, and storage. Laboratory samples of potentially infectious materials shall be placed in labeled coolers or mailing packages immediately or as soon as feasible in order to prevent leakage or breakage.

- Specimens for transport shall be placed in a double container if a container is leaking or is contaminated on the outside. Specimens for transport must conform to U.S. Postal Regulation 124.383a, which defines packaging requirements for etiologic agents.

- Unfixed slides from cancer detection activities shall be treated as potentially infectious materials.

- Equipment which becomes contaminated with blood or other potentially infectious materials shall be decontaminated prior to shipping or repair. Portions that remain potentially contaminated must be identified by a readily observable label or tag.

- If equipment cannot be decontaminated, biomedical technicians and equipment repair personnel will be advised when equipment requiring repair may be contaminated.

- Broken glass that may be contaminated with blood or other potentially infectious materials must not be picked up by hand, even when wearing gloves. A broom, dustpan, tongs, or other mechanical means are to be used. Equipment used must be disinfected afterwards with a detergent washing followed by a soak in a sodium hypochlorite (household bleach) solution for at least five minutes, or in another EPA approved intermediate level disinfectant.

7.6Personal Protective Equipment

A. General Protective Equipment

- Each supervisor is responsible for ensuring that staff is using Universal Precautions when exposed to blood or other potentially infectious materials.

- The following items are considered personal protective equipment:

- disposable vinyl or latex gloves;

- non-disposable utility gloves used in housekeeping tasks;

- masks, eye protection devices, and face shields;

- disposable gowns or aprons; and

- mouth pieces or resuscitation bags. Uniforms are not considered personal protective equipment, but clothing.

- Each shift or unit supervisor is responsible for assuring the easy accessibility of personal protective equipment in the proper sizes for use by occupationally exposed employees.

- Personal protective equipment is provided, maintained, cleaned and repaired at no cost to the employee. Each instance in which an employee is performing an activity that results in occupational exposure without the use of proper protective equipment must be documented. If the non-use of appropriate protective equipment resulted from an employee's decision to temporarily and briefly decline the use of personal protective equipment because of rare and extraordinary circumstances, which would have prevented the delivery of appropriate care to a patient or client or would have posed an increased hazard to the safety of the worker or coworkers, the supervisor will document those circumstances.

- The employee's supervisor is responsible for assuring this documentation in the form of a memo to the record, in addition to following procedures described in the section of this document on post exposure evaluation and follow-up. The supervisor will retain one copy of the memo to the record on file and forward one copy to the Safety Officer in Juneau. Documentation on exposures in which personal protective equipment was not used will be reviewed and evaluated every six months by supervisors and the Safety Officer to determine methods for improving compliance with Universal Precautions as recommended by the Centers for Disease Control and to determine if safer measures can be developed to eliminate preventable occupational exposure.

- Instances in which an employee is found to be negligent in following universal precautions will be reflected in the employee's performance evaluations.

- Defective protective equipment will be reported to the immediate supervisor who will procure replacement items.

B. Clothing

- Clothing that becomes visibly soiled with blood or other potentially infectious materials must be changed immediately. Soiled clothing must be placed immediately into a red or labeled biohazard bag that is leak proof. Universal precautions must be used for processing the laundry unless it is decontaminated before being laundered.

- Personal protective equipment must be removed before the employee leaves the work area. Personal protective equipment such as gloves soiled with blood or other potentially infectious materials must be disposed of in a labeled biohazard bag or color coded red plastic bag.

C. Gloves

- Disposable, FDA-approved latex or vinyl gloves, such as surgical or examination gloves, shall be worn when drawing blood or in other circumstances in which it is reasonably anticipated that the employee may have hand contact with blood, other potentially infectious materials, mucous membranes, or non-intact skin, as specified in site-specific procedures.

- Disposable gloves shall be replaced as soon as feasible if they become torn or punctured.

- Disposable gloves shall be changed between patients with hand washing after removal of gloves. If hand washing facilities are not available, antiseptic towelettes or cleansers must be used.

- Disposable gloves shall not be washed or reused.

- Employees carrying out housekeeping/cleaning activities involving blood or other potentially infectious materials shall use non-disposable utility gloves.

D. Housekeeping

- All equipment and environmental and working surfaces shall be cleaned and disinfected after direct contact with blood or other potentially infectious materials.

- Tables that are used for clinics shall be cleaned with disinfectants. A disposable protective covering shall be used for protection of the work surface when blood or other potentially infectious materials are being collected or processed. If at any time a work surface becomes grossly contaminated, the protective covering shall be removed and the surface shall be cleaned and disinfected immediately.

- Protective coverings will be changed on patient examining tables between patients. Liners of tables for blood drawing only need to be changed if the surface becomes visibly contaminated.

- If there is a potential for blood or other potentially infectious materials to drop or flake off the disposable protective covering, the covering shall be considered to be regulated waste and must be disposed of accordingly. For example, a spot of blood on a disposable table covering is not considered regulated waste. However, if a sufficient quantity of blood is spilled so that it would drip if the covering is compressed or wrung out, it would be regulated waste.

- Spills of blood or other potentially infectious materials must be promptly cleaned up while wearing gloves. Visible materials must first be removed with disposable towels or other appropriate means and disposed of according to approved biohazard methods. A detergent should be used to clean the surface followed by a fresh 1:100 sodium hypochlorite (household bleach) solution or other EPA approved intermediate level disinfectant. The surface should be kept wet with the bleach and water solution for five minutes and then allowed to air dry.

- Biohazard plastic bags, either labeled or color coded, shall be used for the disposal of all paper and non-sharp waste that is grossly contaminated with blood or other potentially infectious materials and is considered to be regulated waste. For instance, plastic biohazard bags are to be used to line all trash receptacles for articles saturated with blood or other potentially infectious materials.

- A second biohazard bag or container must be used if outside contamination of the first waste container occurs, or if there is a possibility the first bag may leak.

- Garbage cans lined with biohazard bags are to be checked each time the biohazard liner is removed to ensure that there is no gross contamination of the garbage can. If there is, the can is to be cleaned with a detergent solution and then disinfected with a 1:100 household bleach solution.

- Broken glass that may be contaminated with blood or other potentially infectious materials shall not be picked up directly with hands. Instead, tongs, brooms, and dust pans are to be used. Implements used to pick up contaminated glass are to be decontaminated after use.

- Broken glass that may be contaminated shall be deposited in a sharps container. If the quantity or size of the glass debris is too large to fit into a sharps container, another, suitably sized, hard-sided container shall be used to contain the debris. This container shall be suitably labeled as described in the section of this document on Biohazard Labeling and Color Coding and disposed of in the same manner as a sharps container.

- Sharps containers are adequate when:

- closeable (with both temporary and permanent lids so that the container can be secured when filled or closed when not in active use or during transportation);

- puncture resistant;

- leak proof on sides and bottom; and

- labeled with a biohazard sign or color coded red;

- Sharps containers are adequate when:

- Sharps containers shall be:

- available for immediate disposal of sharps in locations where sharps are used;

- maintained in an upright position;

- kept closed when transported or when not in active use; and

- replaced when three-quarters fall.

- Sharps containers shall not be emptied, cleaned manually, or handled in any manner which would expose employees to the risk of puncture, abrasion, or other skin injury.

- Wastes

- Regulated wastes include liquid or semi-liquid blood or other potentially infectious materials; contaminated items that would release blood or other potentially infectious materials in a liquid or semi-liquid state if compressed; items that are caked with dried blood and are capable of releasing infectious materials during handling; contaminated sharps; and pathological and microbiological wastes containing blood and other potentially infectious materials.

- Regulated waste must be placed in containers that are closeable, constructed to contain all contents and prevent leakage of fluids during handling, storage, transportation or shipping.

- Liquid blood or other potentially infectious liquid materials may be flushed down drains or commodes served by a central sewage treatment plant.

- Regulated wastes generated at field clinics or in locations away from permanent facility shall be transported back to a facility where proper disposal can occur.

- Disposal of regulated waste shall occur in conformity with applicable laws and regulations of the Alaska Department of Environmental Conservation.

- Laundry

- Laundry contaminated with blood or other potentially infectious materials will be handled as little as possible. Such laundry will be placed in appropriately marked (biohazard labeled or color coded red bag) bags at the location where it is used. Such laundry will not be sorted or rinsed in the area of use.

- Alternatively, if all soiled laundry is handled using universal precautions, an alternative color or label for laundry bags/containers may be used as long as employees are trained to recognize them as containing soiled laundry that requires the use of universal precautions.

7.7Biohazard Labeling and Color Coding

A. Shift or unit supervisors are responsible for ensuring that biohazard labels are affixed to containers of regulated waste, refrigerators and freezers containing blood or other potentially infectious materials, and other containers used to store, or ship blood or other potentially infectious waste.

B. The universal biohazard symbol shall be used. The label must be fluorescent orange or orange-red.Labels must be secured to the package or container by string, wire, adhesive or other method to prevent the unintentional loss or removal of the label.

C. Red bags or containers may be substituted for labels.

D. Regulated wastes that have been decontaminated, such as wastes that have been properly autoclaved, are exempted from the labeling/color coding requirement.

E. Supervisors in work areas that may generate regulated wastes are responsible for obtaining appropriate labels, sharps containers, and color coded red bags.

7.8Employee Training

A. All full- and part-time employees judged subject to occupational exposure must participate in all components of a training program, which is to be provided during working hours and at no cost to the employee.

B. Training as specified in Section F, below, will be provided:

- before immunization and within 10 working days of initial assignment to tasks where occupational exposure may occur;

- after the effective date of the Alaska Administrative Code regulations governing occupational exposure to blood-borne pathogens; and

- at least annually thereafter.

C. For employees who have received training on blood-borne pathogens in the year preceding the effective date of the regulations, only training with respect to the provisions of the regulations that were not included needs to be provided.

D. Additional training must be provided to employees when there are any changes in tasks or procedures affecting the employee's occupational exposure. Arrangements for such training will be assured and documented by the employee's supervisor within 10 working days of new task/ procedure initiation.

E. Material appropriate in content and vocabulary to educational level, literacy, and language of employees must be used.

F.The training course, which will be developed and reviewed at least annually, must contain at a minimum the following elements:

- a copy of the state regulations and an explanation of their contents;

- an explanation of the facility's Blood-borne Pathogen Exposure Control Plan;

- a general explanation of the epidemiology and symptoms of blood-borne diseases;

- an explanation of the modes of transmission of blood-borne pathogens;

- the recognition of tasks that may involve exposure;

- an explanation of the use and limitations of methods that will prevent or reduce exposure including appropriate engineering controls, work practices, and personal protective equipment;

- an explanation of the types, use, location, removal, handling, decontamination, and disposal of personal protective equipment;

- an explanation of the basis for selection of personal protective equipment;

- information on Hepatitis B immunization, including efficacy, safety, method of administration, benefits, and that it will be ordered free;

- an explanation of the procedure to follow if an exposure incident occurs, including the appropriate actions to take, the method of reporting the incident including whom to contact, and the medical follow-up that will be made available;

- information on post exposure evaluation and follow-up that the employer is required to provide for the employee following an exposure incident; and

- an explanation of the signs and labels and color coding required for hazards or regulated waste.

G. A copy of your facility's Exposure Control Plan will be made available when requested by an employee or a member of the public.

H. While various types of training aides may be used in training courses, training must provide opportunity for interaction between trainees and instructors.

7.9Hepatitis B Vaccine

A. Hepatitis B vaccine is available free of charge to all full- and part-time employees with occupational exposure to blood or potentially infectious materials. Vaccination will be made available during duty hours and at a reasonable time and place.

B. All employees with occupational exposure are encouraged to receive Hepatitis B vaccine.

C. Vaccines will be administered under the direction of a licensed medical professional. Unit supervisors are responsible for providing a written authorization for the health care practitioner to provide vaccination at no cost to the employee and for assuring vaccine administration.

D. Employees may receive or refuse vaccination only after attending the required training course on blood-borne pathogens.

E. The first dose of vaccine must be given within 10 days of an employee's assignment to a position involving occupational exposure unless the employee signs a declination form (Hepatitis B Declination Form found in Appendix B). Signing the declination form does not preclude the employee from receiving the vaccine at a later date if he/she changes his/her mind.

F.In the case of employees who were already in positions with occupational exposure on the effective date of the Alaska regulations on blood-borne pathogens and who have not previously received the Hepatitis B vaccine, the first dose of vaccine must be offered within 10 days of completion of the required employee training unless the employee signs a declination form.

G. Screening for antibody to Hepatitis B virus is not routinely offered before or after vaccination and cannot be required.

H. The following types of proof of immunity to Hepatitis B are acceptable: (a) a provider verification of immunization with dates; (b) physician documentation and laboratory confirmation of current or prior infection; or (c) documentation of laboratory confirmed immunity. The laboratory referenced in (b) and (c) above, must be licensed or certified to provide this service in the state or territory in which it is located.

I.Unit supervisors are responsible for employee compliance in obtaining the vaccine or signing a declination form within 10 working days of assignment and for assuring timely compliance with dates for completing the series.

J.Booster doses will be provided if recommended by the U.S. Public Health Service.

K. If an employee terminates employment prior to completing the vaccination series, the employer is not responsible for completion of the series.

L.Accurate records of immunization status will be forwarded to and maintained in the employee's permanent personnel file and the contracted medical records holding facility.

8.0Interim Tuberculosis Exposure Control Plan

8.1Purpose

To outline responsibilities and establish guidelines for DHSS employees who may reasonably come in contact with tuberculosis (TB) germs while performing their jobs.

8.2Scope

Applies to all employees who must work in environments where there exists a moderate level of risk of exposure to tuberculosis.

8.3Objective

To reduce the level of exposure risk to employees by implementing changes in work procedures and potentially providing annual TB tests. In addition, in-service and other types of educational efforts will be utilized to provide pertinent information regarding the disease to DHSS employees.

8.4Facts Concerning Tuberculosis

Tuberculosis is a disease caused by a tiny germ called Mycobacterium tuberculosis. M. tuberculosis is carried in airborne particles, or droplet nuclei, that can be generated when people who have pulmonary or laryngeal TB sneeze, cough, speak, or sing. The infectious particles are very tiny, and normal air currents can keep them airborne for a long time period and spread them throughout a room. Infection occurs when a person inhales droplet nuclei containing M. tuberculosis and these nuclei traverse the mouth or nose and reach the lungs. Once in the lungs, the organisms are spread throughout the body. Usually from 2-10 weeks after initial infection with M. tuberculosis, the immune response limits further multiplication and spread of the germ; however, some of the germs remain dormant and viable for many years. This condition is referred to as latent TB infection. Persons with latent TB infection usually have positive TB skin test results, but they do not have symptoms of active TB, and they are not infectious. In general, people who have latent TB infection have approximately a 10% risk of developing active TB disease during their lifetimes. This risk is greatest during the first two years after infection. Immuno-compromised persons have a greater risk for the progression of latent TB infection to active TB disease; HIV infection is the strongest known risk factor for this progression.

TB infection is not spread on dishes, drinking glasses, eating utensils, toilet seats, or other objects, including food. The probability that a person who is exposed to M. tuberculosis will become infected depends primarily in the concentration of infectious droplet nuclei in the air and the duration of exposure. Environmental factors that enhance the likelihood of transmission include: a) exposure in relatively small, enclosed spaces; b) inadequate local or general ventilation which results in insufficient dilution or removal of infectious droplet nuclei; and c) recirculation of air containing infectious droplet nuclei.

8.5Program Requirements

It is of utmost concern to our department that our employees be protected from exposure to tuberculosis while on the job. Therefore, it is important that the following program requirements be met:

- Each division conduct a self-inspection to identify which of their employees might be at risk of infection. It should be remembered that infection is spread through repeated exposure indoors from a diseased person. It would normally take twenty hours of exposure to a TB infected person for an individual to become infected with the disease. Employees who work in residential work environments are considered "at risk."

- The more difficult determinations must be made in relation to all other employees. The Epidemiology Section of the Division of Public Health monitors the status of TB throughout the state. Certain geographical areas have higher rates of infection. This information should be considered when identifying specific positions in locations which are at risk. The following steps must then be taken as follows:

- All identified employees will receive initial training, which recognizes job situations in which exposure may occur and explains fundamental information regarding the disease.

- Efforts should be made to alter work procedures or processes to reduce the level of risk. Special emphasis should be directed at increasing the level of fresh air flow through indoor work environments. For instance, opening an exterior window, which might be adjacent to a tightly cramped client waiting room, would help dissipate potential TB germs. The type of work procedure alteration will be dictated by the level of the perceived risk.

- The great majority of DHSS positions will not be identified as "at risk." However, employees may still express concern that they could become infected with TB. If this occurs, the location manager should:

- Attempt to assess the true level of risk involved.

- Based on the true level of risk, make necessary alterations to work procedures or processes. Again, special emphasis should be given to the issue of ventilation.

- Provide training to concerned employees which recognizes job situations in which exposure may occur and explains information relating to TB.

9.0Safety and Health Inspections

Risk assessment and control are very important elements of a successful safety program. Safety and health inspections help identify existing or potential dangers in the workplace. They focus primarily on unsafe acts and unsafe conditions and help provide corrective measures before these acts or conditions become serious enough to cause an accident.

Safety inspections provide valuable information such as:

- The level of compliance to safety legislation and organizational safety standards.

- The level of management commitment and participation.

- Evaluating the effectiveness of safety program practices and procedures.

- The effects of change (i.e., technology) on safety performance.

- Identification of improper employee actions (i.e., unsafe acts).

- Deficiencies in equipment

- Providing a communications system to keep all participating personnel informed.

- Identification of hazardous situations.

- Serving as a barometer of worker safety awareness and morale.

9.1Annual Inspections

At least once annually a safety inspection should be conducted at each department location. Each division director will be responsible for ensuring that this occurs within his or her division. The Department Safety Officer is available to perform these inspections. Division Managers should contact the Safety Officer and arrange for an inspection.

9.2OSHA Consultation Inspections

The Alaska Department of Labor provides consultation inspections at the request of employers. These inspections help safety and health programs comply with state statutes without penalties imposed for deficiencies. These inspections are helpful when a state OSHA standard needs to be adapted for a specific site or situation. All deficiencies noted on these inspections must be corrected according to OSHA guidelines. Divisions are encouraged to utilize consultation inspections and these can be scheduled through the DHSS Safety Officer.

9.3OSHA Compliance Inspections

The State of Alaska Department of Labor can visit a DHSS establishment on a "no notice" basis. If a violation of a safety standard is documented by an inspection officer, a citation will be issued against DHSS by mail to the affected location or to the division director.

State inspection compliance officers generally concern themselves with safe working practices, use of prescribed protective equipment, adequacy of protective equipment, guarding of machines, equipment configurations with respect to operation protection, and written safety and health programs.

9.3.1Responsibilities of Division Compliance Inspections

- If in Juneau, notify the Safety Officer and invite him/her to accompany the State Inspector when any DHSS facility is inspected.

- Record violations detected by the inspector. Include the Safety Officer as part of the closing conference session with the DOL inspector.

- In the event of a citation, ensure it is posted on the bulletin board nearest to the violation until it has been abated or vacated.

- If the citation is questionable or should be aggrieved, the Division Director should request an informal hearing with the Department of Labor.

- Ensure correction of a violation within the abatement period or file (in writing) for an extension. If an extension is filed, a copy should be sent to the Safety Officer.

- Upon completion of corrective action, certify by date and signature at the bottom of the citation form that each violation has been abated. Mail form to the State Department of Labor with a copy to the Safety Officer.

9.4Hazard Classification Rating System

One of the largest benefits of hazard classification is the establishment of priorities. The hazard posing the greatest risk should be given priority in the correction process. These hazard classifications can be used to describe the potential severity of loss in the event of an accident.

Hazard classification rating is intended to give supervisors and inspection teams guidance as they attempt to discover root causes of problems they note. This effort to identify the basic causes of the items uncovered on inspections is a key to permanent remedy.

The hazard classification rating system is as follows:

- Class A HazardA condition or practice likely to cause permanent disability, loss of life or body part, or extensive loss of structure, equipment or material.

- Class B HazardA condition or practice likely to cause serious injury or illness, resulting in temporary disability or property damage that is disruptive but not extensive.

- Class C HazardA condition or practice likely to cause minor (non-disabling) injury or illness or non disruptive property damage.

- Class D HazardA condition that could cause minor injury or is a minor housekeeping problem that can be easily corrected.

For clarification purposes, the following examples of hazard classification ratings are provided:

- Class A Hazard

- Example 1. A backhoe is performing a trenching procedure at a DHSS location. The swing radius of the machine extends directly over a walkway which is used by employees.

- Example 2. Guards are missing on rotating equipment.

- Class B Hazard

- Example 1. The sidewalk outside a DHSS clinic is missing a large piece of concrete. The area has not been blocked off.

- Example 2. A maintenance employee has mixed two hazardous chemicals in an unmarked container.

- Class C Hazard

- Example 1. Office employees work at a leased facility in which there is no fresh air ventilation.

- Example 2. Poor lighting conditions exist at night in the facility repair shop.

- Class D HazardExample 1. Clients have tracked snow and ice on top of the linoleum hallway.Example 2. A Social Worker in a remote location fails to place a winter survival suit in his/her automobile during a home visit. Temperatures are -30°

Supervisors are encouraged to perform informal safety inspections often. All employees are responsible for reporting hazardous conditions

10.0 Hazardous Material Management Program

10.1Purpose

To outline responsibilities, establish procedures, guidelines, and proper practices for handling, storing, redistributing and/or disposing of surplus hazardous materials and hazardous waste.

10.2Scope

Applies to all DHSS employees who may come in contact with hazardous materials as a part of their employment.

10.3Objective

- To prevent accidents and loss to the State of Alaska, its employees and the public.

- To reduce risks associated with handling, storing and/or disposal of hazardous materials.

- To assure compliance with all applicable laws concerning hazardous materials.

10.4Definitions

- Accumulation AreaAn area where surplus hazardous materials or waste is collected and temporarily stored prior to redistribution, treatment or disposal.

- CFRCode of Federal Regulations.

- DisposalThe disposition of contained, hazardous waste.

- Waste ProducerAny person whose act or process produces hazardous waste.

- Hazardous MaterialMaterial that poses physical or health hazards. It includes infectious agents, laboratory, janitorial and other chemicals.

- Hazardous WasteAny material intended to be discarded which is either toxic, ignitable, corrosive, or reactive. Refer to 40 CFR 261 for complete definitions. Listed wastes include spent/used solvents and discarded commercial chemical products.

- RedistributionPart of the Hazardous Material Minimization Program. Provides method for tracking and redistribution of surplus chemicals.

10.5Hazard Communication

10.5.1Responsibilities

- Management — Division Directors

- Must ensure that all employees who come in contact with hazardous materials as part of their employment are:

- Provided necessary tools, equipment, training and information concerning safe work practices; and

- In compliance with safety policies, procedures and regulations pertaining to hazardous materials.

10.5.2Program Requirements

- Division Directors will ensure that the following program features be present:

- Development and maintenance of an up-to date inventory of chemicals used by division employees in the workplace.

- Collection of Material Safety Data Sheets (MSDS) on all chemicals and materials used in the workplace, and make them readily available to supervisors and employees in the work areas.

- Assurance that containers have identification labels applied to them.

- Training for employees who work with chemicals and toxic materials in the hazards of those chemicals and in emergency procedures.

- Employee training will include:

- Methods and observations that may be used to detect the presence of hazardous chemicals in the work area such as continuous monitoring devices, odors, visual appearance of hazardous chemicals, etc.

- Physical and health hazards of the chemicals in the work area.

- Measures employees can take to protect themselves from these hazards, including changes in work procedures and the wearing of personal protective equipment.

- Details of the hazard communication program developed by DHSS, including an explanation of how employees can obtain and use the appropriate hazard information.

- Inform contractors who will be working regularly in areas where hazardous substances will be used. Also, hazardous substances used by contractors on DHSS property need to be identified and material safety data sheets generated for employee review.

10.6Hazardous Material Users of Hazardous Waste

DHSS management should always try to substitute existing hazardous materials with biodegradable or less toxic products. This is a key element in hazardous waste stream reduction. Surplus hazardous materials must be removed from work areas pending redistribution. In compliance with local, state and federal requirements, materials deemed to be hazardous waste must be shipped off site promptly.

To help facilitate compliance with these requirements, surplus hazardous materials and suspected hazardous waste should be properly identified, containerized and promptly moved to designated hazardous material accumulation and collection areas.

Staff (hazardous material users) responsibilities are outlined below.

- Hazardous material users are responsible for identifying and designating:

- Surplus hazardous materials that are no longer needed by them and may possibly be used by others;

- Hazardous materials where there is no apparent future use (i.e., expired shelf use, chemical make-up is unknown or unidentifiable, spent fuels and solvents, etc.); and

- Quantities of hazardous materials that exceed the allowable limits for safe storage.

- Surplus hazardous materials and suspected hazardous waste should be properly containerized and prepared for storage in the approved designated hazardous material collection areas (i.e., fume hoods, appropriate storage cabinets, etc.).

- Hazardous material must be properly containerized in its original container, DOT specified containers, or other containers identified for hazardous material type.

- Fill out and affix required hazardous material labels on containers. At the time when the accumulation of a material begins, the date should be clearly marked and visible for inspection on each container.

- Participate in required training programs involving hazardous material handling, management, hazard communication, safety training programs, etc.

- General rules for proper management of surplus hazardous materials and suspected wastes include, but are not limited to:

- Accumulation of materials in containers larger than 55 gallons must meet DOT specifications;

- If accumulating ignitable materials, care must be taken to store the material in accordance with applicable fire safety codes and procedures;

- Hazardous materials should never be simply abandoned at hazardous material collection sites;

- Depending on the chemical hazard presented, hazardous material users must receive proper training and utilize personal protective clothing and equipment as required (i.e., indicated on Material Safety Data Sheets, container labels or mandated by law); and

- Attach to the container any special hazard information gained as a result of a known incompatible mixture or a chemical test, such as:

10.7Labeling Of Hazardous Material Containers

- Procedures for hazardous material labeling apply to all DHSS employees who work with hazardous materials.

- Labeling: To help ensure the correct storage compatibilities of chemicals and other hazardous materials, efficient hazardous material management and safety operations, hazardous materials in use, stored for future use, or disposal must be labeled in accordance with local, state and federal law. Labeling should include:

- Hazardous chemical or component in a container will be identified;

- Display appropriate hazard warnings; and

- When known, include the name and address of the manufacturer, importer or responsible party.

- The hazard warning system that has been adopted by DHSS is the NFPA 704 (National Fire Protection Association) hazard marking and color coding system.

- To maintain consistency of labeling and coding systems for disposal and safety purposes, the NFPA numerical rating (0-4), representing the degree of hazard, must be displayed on all hazardous material container labels. Household or commercial cleaners, solvents and paints in containers in quantities of less than five gallons are exempt from this provision.

- The NFPA 704 system is designed to communicate health (toxicity), fire (flammability), corrosiveness and reactivity (stability) information to individuals working with hazardous materials. An example of an NFPA label (704M diamond) is illustrated below. The numbers 0-4 are NFPA ratings representing the degree of hazard. A "0" represents a low, or no hazard rating condition.

- A "4" represents an extreme hazard. Color coding identifies the nature of hazard and the required storage locale and atmosphere. Blue (left) represents Health; Red (top) Flammability;

- Yellow (right) Stability; and White (bottom) represents "Special Information" which is followed with hazard symbols. The NFPA 704 M labeling systems provide a simple mechanism for easy identification, separation and storage of hazardous materials based on chemical compatibility and for safety and emergency response.

- Containers that are to be shipped must be labeled with the Department of Transportation labeling system on the outside of the container.

- Hazardous material labels are not intended to be a complete or only source of safety hazard information. Material Safety Data Sheets (MSDS) should be used in addition to the label information. MSDSs are probably the best source of safety information available and should be requested, maintained, and made available to all employees who may come in contact with hazardous materials. MSDSs provide detailed information such as:

- Material Identification Hazardous

- Ingredients/Identity

- Physical/Chemical Characteristics

- Fire and Explosive Hazard Data

- Reactivity Data

- Health Hazard Data

- Precautions for Safe Handling

- Control Measures

- Material Safety Data Sheets must be maintained by all divisions working with or around hazardous materials.

10.8Chemical Spills

- Any leaks or spills must be promptly reported to the Fire Department in your locality by calling 911. The caller must provide a detailed description of the spill and chemical(s) involved. Advise whether the chemical is flammable or whether there is a threat of fire or asphyxiation.

- Divisions and laboratories using, generating and/or possessing hazardous chemicals should maintain a well stocked chemical spill kit (accessible location) at all times.

- General rules and precautions include:

- Provide immediate attention and care for anyone who may have been contaminated by the spill.

- Determine chemical nature of spill.

- Notify responsible parties such as division director, supervisors, General Services (if spill occurred in leased facility), etc.

- If the chemical nature of the spill is unknown, treat the spill as you would a highly toxic hazardous material and take all safety precautions.

- Ventilate area of spill.

- Consider the possibility of evacuation of non-essential personnel from the spill area.

- Consult reference materials, including but not limited to, the Material Safety Data Sheets for the item or items spilled. The MSDS will provide information on the potential hazard involved (Sections 1-6); spill and disposal procedures (Section 7); protective equipment and measures (Section 8); storage and handling data (Section 9); and transportation data (Section 10). Utilize this information in the management of the spill.

- After the appropriate safety measures have been taken, including but not limited to, the recommendations set forth in the MSDS, initiate a location spill plan. Non-ignitable, low toxicity liquids or solids not generating dangerous gases can be handled by responsible and knowledgeable division personnel, if the volume is sufficiently small. In all other instances, assistance in managing chemical spills must be requested by your local fire department or emergency response team. Contact the Department of Environmental Conservation/Division of Spill Prevention and Response at:

- Central (Anchorage)269-3063269-7648

- Northern (Fairbanks) 451-2121451-2362

- Southeast (Juneau)465-5340465-2237

11.0Hearing Conservation Program

11.1Purpose

To outline responsibilities and establish guidelines for employees who work in environments containing excessive noise.

11.2Scope

Applies to all DHSS employees who must work in areas that exceed 85 decibels for an eight-hour time period.

11.3Objective

Hearing loss is a common workplace injury, all too often ignored because it usually happens gradually over a period of time. A hearing conservation program has been established to protect employees from excessive work related noise exposure through changes in work procedures, engineering controls and personal protective equipment.

11.4Program Requirements

In all cases, where sound levels exceed 85 decibels over a time-weighted eight-hour average, a hearing conservation program must be initiated.

The hearing conservation program should contain the following features:

- Noise MonitoringWhen information indicates that any employee's exposure may equal or exceed an eight-hour time-weighted average of 85 decibels, a monitoring program shall be implemented. A dosimeter may be used to measure noise levels over a period of time while a sound level meter can measure the intensity of sound at a given moment. Both are very useful devices for determining noise levels.

- AudiogramsAn audiometric testing program needs to be implemented, which makes audiometric testing available to employees whose exposures equal or exceed an eight-hour time-weighted average of 85 decibels. The program shall be provided at no cost to the employee. Within six months of an employee's first exposure at or above the action level, DHSS is required to ensure that a baseline audiogram is established, against which subsequent audiograms can be prepared. At least annually, thereafter, a new audiogram for each exposed employee must be obtained.

- Constructive ActionWhen it is known that excessive noise exists in the workplace it is important for our department to take constructive action. First, there may be changes in work procedures that can be implemented which reduce noise levels. Second, engineering controls can sometimes help. For instance, say a maintenance employee at one of our residential facilities uses a chainsaw to trim trees that are located on DHSS property. The saw he/she normally uses has a decibel level of 117 decibels. By placing an attachable muffler on the saw he/she can reduce the decibel level by l0 decibels. Third, when changes in work procedures or engineering controls are not possible or affordable, personal protective equipment can be used.Using the example above, this employee would also want to wear ear protection while operating the chainsaw because the addition of the muffler would not eliminate the hazard (i.e., excessive noise).The wearing of ear plugs is a cheap and effective means of reducing noise exposure. Employees should be encouraged to use them when they work with loud equipment.

12.0Emergency Action Plans

12.1Purpose

To establish a uniform policy that will ensure the safe evacuation of DHSS employees in the event of fire or other emergencies.

12.2Scope

Applies to all department locations.

12.3Objective

To reduce the risk of injury to DHSS employees in the event of fire or other emergencies by establishing site-specific procedures that serve as a guide for the evacuation process.

12.4Program Requirements

An emergency action plan (EAP) is a written document required by particular OSHA standards. The purpose of an EAP is to facilitate and organize employer and employee actions during workplace emergencies. The elements of the plan must include, but are not limited to:

- evacuation procedures and emergency escape route assignments;

- procedures to be followed by employees who remain to operate critical plant operations before they evacuate;

- procedures to account for all employees after an emergency evacuation have been completed;

- rescue and medical duties for those employees who are to perform them;

- means of reporting fires and other emergencies; and

- names or job titles of persons who can be contacted for further information or explanation of duties under the plan.