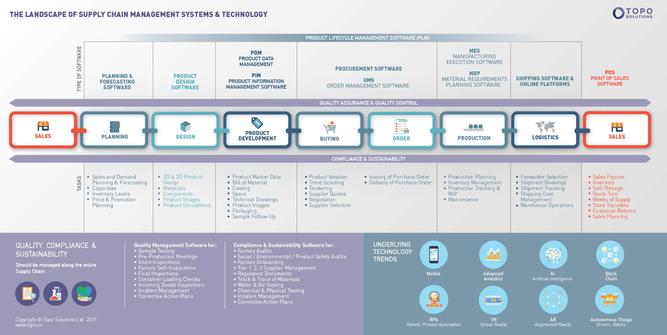

Across industries, there is a massive shift underway touse emerging artificial intelligence (AI) technologies to improve bothprocesses and systems, especially in supply chain management to improvedecision support and improve productivity. AI is the process of learning fromexisting data while supplementing human work to achieve desired goals morequickly, more efficiently and at lower costs. This practice is known as human augmentation—using AI technologies to increase ourhuman capacities and capabilities.

Today, AI is augmenting manyhuman activities across a wide range of activities, including softwaredevelopment, cloud-based services, data centers, manufacturing, supply chainmanagement, distribution, industrial robots, automated voice synthesis, andmore. In all of these areas, new technologies are used to support human workand optimize product development and delivery in a range of industries.

HumanAugmentation Market

All this activity is leading to afast-growing market for AI-developed technologies. The Global Human AugmentationMarket could reach $17 billion by 2026, according to a 2021 report prepared bymarket researchers Global Industry Analysts Inc.

Specifically, in supply chain management, human augmentation will take animportant sliver of that total, as it’s anticipated to grow to $1.3 billion inthe next few years. Leading experts in artificial intelligence agree. Accenture’s head of applied intelligence Sanjeev Voohrarecently noted he’s seeing a massive move toward companies using analytics,AI and automation practices to help companies make the digital transformationfor their businesses.

A potentially massive market isin the making. I believe that digital transformation is underway, and humanaugmentation with AI is integral for the success of the supply chain. Modernsupply chains involve a complex web of people, companies, data, transportation,and other resources to help move goods and services from suppliers tocustomers. Using AI and human augmentation in supply chain management couldtransform the existing paradigm through a mix of task replication or tasksupplementation.

Let’s look at some of the waysthat human augmentation can propel this supply chain transformation forward.

Know thePurpose

AI is often brought into the supply chain for a specificpurpose. However, AI doesn’t work on its own. It must have elements of humanaugmentation to allow for the AI model to function effectively. As part of theAI and digitalization process, it is imperative that human experts consistentlyinteract throughout the learning process to enhance and further shape the AImodel and then meet the unique needs of the business. Together, humans and theAI system work together to produce the highly specific and desired outcomes.This results in higher payback over the long term that organizations willdiscover as much more valuable to them.

In business, we must take responsibility to leverage AImodels with correct information. When you know the purpose of processes andsystems, and provide AI models accurately to help your supply chain management,then you can drive the desired outcomes.

Company teams working with the supply chain’s materialhandling and logistics must teach the AI model the correct information—thepurpose—using machine learning. Doing so will help to safeguard the companyagainst any misreads or errors moving ahead.

Transfer ofKnowledge

Human interaction drives organizational planning andinteraction. Knowledge transfer can help teach AI not only the right processbut the learnings from past behaviors. Put these two areas together, and youcan see how human augmentation can supplement the AI model for a moreefficient and effective supply chain.

AI models are less flexible when it comes to adjustmentsinvolving prior background and experience. If AI is incorrectly taught, it mayproduce incorrect decisions and potentially negative outcomes. That canadversely impact the organization and its supply chain.

It’s incumbent on corporate teams to leverage theirknowledge base for AI to work properly. When done right, these experiences willensure the AI model is on the right path.

Top-LevelExecution

Your senior leadership and departmental teams mustexecute properly. Your organization may have a great new AI system to helpstreamline the supply chain, but there needs to be organization-wide supportand an internal understanding of your AI models.

For a well-oiled AI supply chain to work, it’s up totalented workers to build and maintain large, standardized datasets, removeexisting data silos, and provide good communication to trading partners,including suppliers, carriers and customers. Employees should evaluatecloud-based AI solutions to ensure decision support in the supply chain.

If execution falters at any point, the promise of AI toboost supply chain effectiveness may also fall short. Companies may find thatthere is no net positive impact. A move to AI must use the best informationavailable to ensure that top goals are being met. AI is put to work to betterdrive business strategies, such as reducing inventories or scaling the businessto meet specific areas of demand more quickly. AI can use data and turn it intopurposeful reaction points that impact areas including logistics, operationsand finance.

When you can infuse your supply chain with these AIsuperpowers, your company will benefit in numerous ways:

• Reducesupply chain costs, while improving service levels.

• Getthe correct product to the desired place at the right time.

• Lessenoperational risk through more trusted, sustainable materials and supplymanagement.

• Optimizemaintenance, repair and operations inventory levels.

• Buildtrust in your data and harmonize your data sets in new ways.

• Providerobust decision support to boost employee efficiency and effectiveness.

Businesses that have struggled with supply chain issuessince early 2020 must look ahead to embracing more advanced digitalcapabilities of their businesses. They must use AI models with good data todrive decision-making and find new ways for AI to amplify the supply chain.Only then will we empower the resilience and agility of the supply chain in theyears ahead.

Paul J. Noble is the founder and CEO of Verusen, a provider of supply chain data,inventory and procurement technology.