Enlarge

/

Slaw Device RX Viper pedals, serial number 0002, w/ personalized "AD ASTRA" engraved plate. There aren't many like it, and this one is mine.

Lee Hutchinson

reader comments

53

with 39 posters participating, including story author

Share this story

Share on Facebook

Share on Twitter

Share on Reddit

Last year I spent more money than I ever thought I’d spend on a peripheral to import a set of

Slaw Device BF109 flight sim pedals

. The pedals, when they arrived, weren’t just functional—they were beautiful. Powder-coated aluminum struts, shiny chrome nut-and-bolt accents, those artfully skeletonized foot stirrups—the device was undeniably the work of a skilled craftsman, and the pedals played as good as they look. From space to sky, from

Elite: Dangerous

to

DCS World,

they’ve kicked up my immersion and provided smooth, jitter-free rudder control. I thought I’d be happy with them forever.

Further Reading

Want high-end flight sim pedals? Put $500 in a Polish bank account and contact Slaw

Forever, as it turns out, lasts about 16 months. One fine May afternoon some

new

pedals caught my eye, and my BF109s suddenly looked old and busted. I saw unforgivable flaws where before I'd seen none—the old bumper-arm mechanism wasn’t nearly as smooth as a rolling cam would be, and the foot-in-stirrup position couldn’t be nearly as comfortable as foot-on-floor! And, oooh, look at the colors! The new ones come in

colors!

And now I’m $693 poorer. But, man, my flight sim pedals—

let me show you them!

The dawn of Slaw

The "Slaw" in Slaw Device is Belarusian engineer Wiaczesław Oziabło, who designs and hand-builds pedals in his workshop in Śmiłowo, Poland. Since we last talked to him in early 2015, Oziabło has left his day job to make pedals full time—something that seems to be working out just fine, since he tells Ars he has sold about 240 sets. He’s still a one-man operation, from design to construction to shipping, and the number of orders he’s got stacked up are enough to completely fill his working hours.

Oziabło does not speak English, and I don’t speak Polish or Belarusian, so our conversations are filtered through Google Translate. Still, in the dozens of e-mails we’ve traded over the past months, he’s friendly and always happy to answer questions, even during evening hours here in the US, which is considerably later in Poland. He explained that he has been a tinkerer since childhood—first with toys, and then later graduating to wrenching on motorcycles and designing mechanisms in his head.

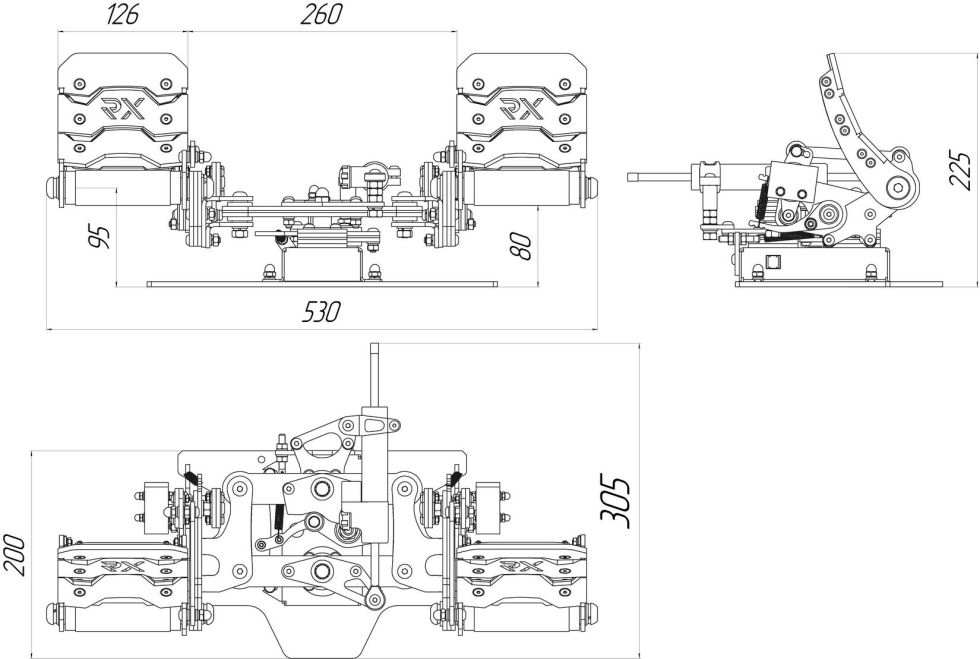

Enlarge

/

Slaw Device RX Viper pedal design diagram. Dimensions are in millimeters.

Slaw Device / Wiaczesław Oziabło

He has a draftsman’s knack for translating mental visions into diagrams on paper. When it comes to sim pedals, he told Ars that he starts with a mechanical concept—how the pedals will fit together and move. "In the beginning I do not pay attention to the appearance. I create a working mechanism," he explained. After constructing that mechanism in

Kompas 3D

, Oziabło works outward, building virtual hardware around the mechanism to achieve the look he's going for.

Specs at a glance: Slaw Device RX Viper pedals

Manufacturer

Slaw Device

Device type

Flight simulator rudder pedals with toe brakes

Axes

Three

Sensor type

Custom magnetic non-contact

Controller precision

13-bit (rudder axis)10-bit (toe brakes)

Interface

USB type-B

Price

$550 plus shipping

To the metal

And what a look. The RX Viper pedals are the third major design Oziabło has released, following the BF109s and a set of

F-16-style pedals

. The Vipers are a work of industrial art—a techno-brutalist lashing of black anodized aircraft grade aluminum struts and steel members, studded with chrome screws and nuts. The two toe brakes feature fitted slabs of interlocking steel that evoke the image of a snake’s belly. I picked black for my RX Viper toe brake color, but Oziabło also offers red and silver.

Advertisement

Oziabło says that the build time on an RX Viper is about 3.5 days, but for this review we cheated a bit. The black RX Viper he sent us was actually the second set built (with serial number 0002) and had been built for a photo shoot. He was on a bit of a build hiatus but could ship this particular set of pedals immediately. Shipping from Śmiłowo to Houston took nine days, and then,

just like last time

, I found myself signing for a heavy box covered in Poczta Polska stickers.

The pedals weigh a massive 7.9kg (about 17.5 lbs), but they still need to be anchored to the floor to keep from moving around in use. The base plate comes pre-drilled with holes for screws if you have a cockpit or sim pit in which to mount them; alternatively, Oziabło suggests affixing them to carpet or a hard floor surface with strong double-sided tape.

Slaw Device video showing RX Viper pedal mechanism in motion.

The entire pedal assembly is built around a center roller cam mechanism. Your heels sit on the floor, and the arch or ball of your foot rests on two knurled bars at the bottom of each toe brake. I’ve found when using the pedals in socks or barefoot that I’m most comfortable when I place the ball of each foot squarely on the bar. Pushing the left or right pedal forward rotates the center cam, which pushes a roller along its path, which in turn draws back on a spring-mounted tension arm. The recentering force is adjustable by turning a screw that lengthens or shortens the spring, and Oziabło ships each set of pedals with a second, longer spring that can be fitted in place of the default one for folks who desire less centering force.

The cam that ships on the pedals has a very soft center. With the long spring in place, the activation force on the pedals can be relatively low and the feeling of passing through the center almost nonexistent. There’s also a second cam with a much harder center that can be swapped in. This cam works best when the pedals are fitted with a hydraulic damper to more closely emulate the feel of aircraft pedals.

Serial number 0002, in the first production run.

Oblique comparison of the RX Viper (foreground) and the BF109 (background).

Profile comparison.

Foot pedal detail, showing interlocking snake-style plates with "RX" logo.

Detail on the central cam and roller mechanism.

The construction is mostly 5mm-thick steel or aluminum plates, which accounts for most of the weight.

The toe brake assembly is a multi-level affair for smooth, linear activation. The box in the background contains the controller electronics for that toe brake.

End-on view of the toe brake sensor and controller assembly, with spring mount points in foreground.

Top-down view of central cam and roller, plus damper mounts.

The toe brake controllers connect to the central controller with these small cables. Also visible here are several toe brake roller bearings.

The main rudder axis bearings are at the top, with the main controller box at the bottom. The controller connects via USB to your computer.

Push it to the limit

The springs and cams and screws make for a highly customizable foot-feel.

Unlike the BF109s, the RX Vipers don’t let you adjust the position or orientation of the toe brakes

; however, the Vipers’ foot-on-floor pedals obviate most of the need for that adjustment in the first place since your feet don’t have to be fitted in stirrups.

(Correction: the toe brakes can be adjusted to three different levels of tilt, and they ship at the minimum setting.)

After about a month of use, I've found that I prefer the foot-on-floor position over the BF109 stirrups. It's simply more comfortable that way for me to use both the rudder axis and the toe brakes.

There are 31 rolling bearings scattered throughout the complex interlinking structure, along with four plain bearings mounted on the upper arm of each toe brake. The arms actually have a small bit of play in them, but they’re purely for assisting with translating the toe brakes’ motion back and forth. The over-engineered appearance of the toe brakes on each side is a big part of the pedals’ mechanical beauty. The complex mechanisms seem

alive

as you shift your feet around on them.

Advertisement

I used the pedals for a while with all the adjustments in their default positions, and everything was harder and stiffer than I was happy with. I’d set up my previous BF109s to require a light amount of force to move, and out of the box the Vipers require a fair amount of actuation force. Numerous sources online (as well as Oziabło himself) indicated that the Vipers are a lot better with a damper in place, so I picked up a

$30 motorcycle steering damper

and affixed it to the pedals’ damper mount, using the parts kit that Oziabło helpfully included with the pedals.

Further Reading

The slowly fading art of flying—and maintaining—Cold War fighter jets

The damper changes the characteristic of the pedals’ activation. It’s almost like editing the response curve, except you’re altering the actual physical force instead of the electronic interpretation of it. With the damper in place, the pedals offer more consistent resistance across the entire range of movement while still keeping that movement easy and frictionless. Full engagement from detent to detent is still easy but also feels modulated and controlled. The pedals also recenter without any rebounding—you can engage them to either detent and let your foot go quickly, and they recenter without bouncing or complaint. The dampers make the pedals feel almost exactly like the controls I got to fiddle with last December when sitting in the cockpits of

several Cold War jets

—smooth and weighty.

The toe brakes are also customizable, with two springs on each side and multiple latch points for the springs to hook into. In the configuration I’m happiest with, about 6.5kg (14.3lbs) of pressure will fully extend one of the pedals to its detent, and about 5kg (13.2lbs) pushes each toe brake forward to the stops. This sounds like a lot, but it

feels

light. The pedals’ mechanism takes up the load so smoothly that the amount of push feels negligible.

The downside to the smoothness and heft is that the Vipers

must

be anchored to something, as mentioned above. The base plate comes with pre-drilled holes that should match up to a number of different cockpit pedal plates. You can also use them to bolt the thing to your floor if you're too brave or crazy to use strong double-sided tape. I stuck mostly with tape, though getting the pedals to sit securely on carpet was a bit of a challenge. Wood or tile floor is less of a problem.

Enlarge

/

The RX Viper pedals do indeed fit on the pedal plate of an Obutto R3volution. Also, I bought an Obutto R3volution, so look for a review of that soon.

Lee Hutchinson

Pedal plates like those used in most home sim-pit setups have their own issues. Secure mounting is possible, but at 530mm from bolt to bolt, the pedals are

hella wide

. Using the RX Vipers in conjunction with a borrowed

Volaire Sim cockpit

required no small amount of ingenuity and zip ties, since the pedals were simply too large to fit on the Volaire tray. I also sent some measurements to

Obutto

Founder and Managing Director Chris Dungan and asked if the RX Vipers would fit in the company's premiere

R3volution cockpit

. Dungan replied that the Viper pedals

should

fit if the cockpit pedal tray is placed in its lowest position (or removed altogether). Later, I was able to verify Dungan's assessment—the pedals do indeed fit without complaint into an Obutto R3volution if the tray is at its lowest setting.

Still, buyer beware: these pedals are considerably wider than most others on the market, so check the measurements of where you intend to mount them before you commit.