In a White Castle just southeast of Chicago, the 100-year-old purveyor of fast food has played host for the past year to an unusual, and unusually hardworking, employee: a robotic fry cook.

Flippy,

as the robot is known

, is no gimmick, says Jamie Richardson, a White Castle vice president. It works 23 hours a day (one hour is reserved for cleaning) and has operated almost continuously for the past year, manning—or robot-ing—the fry station at White Castle No. 42 in Merrillville, Ind. An industrial robot arm sheathed in a grease-proof, white fabric sleeve, it slides along a rail attached to the ceiling, lifting and lowering each basket when ready, immune to spatters and spills. White Castle is so pleased with Flippy’s performance that, in partnership with its maker, Miso Robotics, the chain plans to roll out an improved version, Flippy 2.0, to 10 more of its restaurants across the country.

There were

more than 1.3 million unfilled job openings

at restaurants and hotels as of the end of May, double the number a year earlier, according to the Labor Department. For many restaurants, surviving

the current labor crunch and resulting wage inflation

means using self-service ordering kiosks and other tech tools to

automate away some customer-facing jobs

and

streamline things like online ordering

. But entrepreneurs and industry executives also are trying to tackle a bigger, knottier problem: automating the production of food itself.

Commercial kitchens, especially those in fast food restaurants, have long used automation of one form or another, both on-site and in the preparation of food before it even arrives at a restaurant. The industry has benefited over the decades from innovations ranging from microwave ovens to the drive-through.

The humans working at White Castle No. 42 in Merrillville, Ind., have more time to interact with customers, the company says.

Photo:

Clarissa Bonet for The Wall Street Journal

But what’s happening now is different, says Michael Schaefer, lead analyst of food and beverage developments at Euromonitor, a consumer-trends analysis firm. In the pandemic era, the combination of scarce labor, an unprecedented increase in demand for takeout and delivery, and the minimal margins that delivery allows are compelling restaurateurs to look at technology they might have shied away from before, he says.

Newsletter Sign-up

Technology

A weekly digest of tech reviews, headlines, columns and your questions answered by WSJ's Personal Tech gurus.

PREVIEW

SUBSCRIBE

At the same time,

automation and robotics in general are having a moment

. The falling cost of sensors and actuators, plus the

growing power and accessibility

of the software to drive them, is being combined with systems for automated handling of food that have been used for years in factories that mass-produce things like frozen meals and ready-to-eat snacks, says Doug Foreman, an entrepreneur who created and sold the Guiltless Gourmet and Beanitos brands. His current project,

Tacomation

, which is still just a prototype, is an effort to replace the humans who work behind the counter at restaurants like Chipotle.

It’s not at all clear how many of the attempts to automate food production in restaurants,

commercial “ghost kitchens,”

corporate cafeterias and the like will yield workable solutions. Food automation is littered with the carcasses of ambitious and well-capitalized startups, from

Softbank-funded Zume Pizza’s

January 2020 flameout

to Silicon Valley darling Melt’s

mid-2010s implosion

despite its claims to have developed automated, software-driven smart grills and ovens.

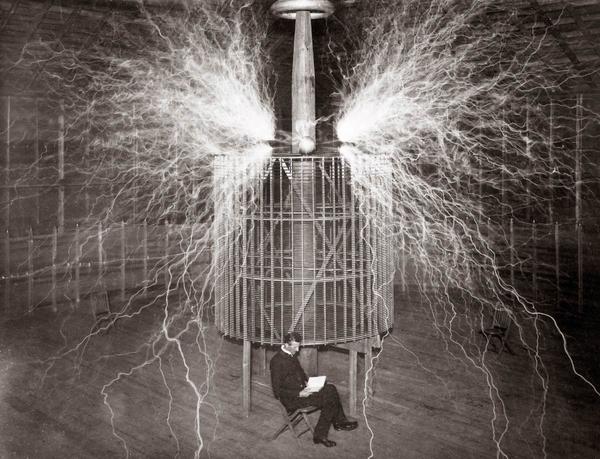

‘Flippy’ runs the White Castle fry station in Merrillville, Ind., 23 hours a day. The chain plans to install 10 more.

One of the biggest challenges engineers face in automating food preparation is that food isn’t like boxes in an automated warehouse or metal panels to be welded together by robots in an automobile factory.

“The real challenge is, how do you make machines that can manipulate this peculiar, non-conformative, multi-dimensionally deformative substance,” says Barney Wragg, chief executive of London-based Karakuri robotics, which is in the midst of installing the first of its “

robotic canteens

” in a corporate cafeteria. That’s engineer-speak for the way that food is tricky to handle, and its characteristics change as you prepare it. Think of how different dry rice is from a mass of its cooked equivalent, adds Mr. Wragg, who at one point in our conversation referred to stew as “a viscous liquid with entrained solids in it.”

More Keywords

Artificial Intelligence’s Big Chill

July 31, 2021

The Novel Material That’s Shrinking Phone Chargers and Making 5G Possible

July 17, 2021

What a Tech Breakup Could Mean for You

July 3, 2021

How AI Is Taking Over Our Gadgets

June 26, 2021

The complexity of cooking is multiplied by the challenges of safe food handling and varied temperatures. Surveying the technology of nearly a dozen startups, it’s clear that the main solution to the problem of food’s complexity is either tackling just a part of the food-preparation process, as with the Flippy robot fry cook, or tackling just one relatively simple type of meal.

Karakuri’s robot can create nearly any meal you like, from a yogurt parfait to a green salad, as long as it’s in some kind of bowl. It resembles a small grain silo with a robot arm at its center, able to raise and lower itself as it moves bowls among cubbies where food is poured, plopped or squirted out like chocolate in the Willy Wonka factory.

Tel Aviv-based Kitchen Robotics’

Beastro cooking robot

operates on this same everything-should-be-a-bowl principle, even though its design looks radically different.

Beastro fills bowls with ingredients from extruders, then moves them to a line of cooking stations, which spin and heat food like little cement mixers.

Karakuri's robot canteen. For the engineers who design such machines, the complexity of cooking is multiplied by the challenges of safe food-handling and varied temperatures.

Photo:

Liam Kelly/Karakuri

Kitchen Robotics is focused on making sure its robot chef can operate more cheaply, on an hourly basis, than the cost of the humans it replaces, says company co-founder Ofer Zinger. Beastro can be leased for $7,500 a month, maintenance included, and is intended to replace two to three people in the back of a small, delivery-only ghost kitchen, he says.

Pizza is another relatively simple food amenable to automated production, hence the rollout of 38 (and counting)

PizzaForno

vending machines across North America, says Les Tomlin, co-founder of the company behind the machines. The company partially bakes its crusts, flash freezes them, then has humans top them at regional kitchens, before they’re delivered to the refrigerated innards of its 80-square-foot machines. When someone orders a pizza from the device’s attached touch screen, the machine bakes it in three minutes.

SHARE YOUR THOUGHTS

Do you welcome our new robot co-workers? Join the conversation below.

Doordash’s February

acquisition of Chowbotics

, the company that makes a salad-making robot, and which has partnered with Kellogg’s to offer college campuses

a cereal-dispensing machine

, points to a future in which more of our meals might be made inside what are essentially souped-up vending machines. Sitting inside existing restaurants or ghost kitchens, their contents delivered to us through apps, consumers might be none the wiser that their meal was prepared by a robot, says Mr. Schaefer of Euromonitor.

Related Video

Low-wage work is in high demand, and employers are now competing for applicants, offering incentives ranging from sign-on bonuses to free food. But with many still unemployed, are these offers working? Photo: Bloomberg News

Del Taco, a chain of about 600 Mexican fast-food restaurants, is partnering with Miso Robotics to be a sort of living laboratory for a forthcoming

drink-filling machine

. The goal is shaving seconds off the time required to fulfill every order, says Kevin Pope, Del Taco’s vice president of operations innovation. Eventually, he adds, the moment a customer makes an order—on a phone, at a kiosk, in a drive through or at the counter—a system will automatically queue up her drink selection for the machine, which takes a cup, fills it with ice, pours the appropriate liquid, snaps on a lid and delivers the finished beverage at the end of a conveyor belt. The humans it works alongside have only to grab it, instead of standing at a soda machine making the drink themselves.

For many of the restaurateurs and executives examining the costs and benefits of bringing more robots into their kitchens, the potential benefits are consistency and reliability as much as savings.

“The 17-year-old fry cook isn’t expensive labor, but the 17-year-old becomes expensive labor if he or she doesn’t show up for work,” says

Ruth Cowan

, a historian who has

researched kitchen automation

. The desire to replace unreliable humans with more-reliable machines has been a primary driver of the adoption of automation for more than 100 years, she adds. That pressure is only intensifying as more and more people question whether they want to work in food service—with its shifting schedules, relatively low wages and physically and mentally demanding workload.

Human customers at the White Castle in Merrillville, Ind.

Photo:

Clarissa Bonet for The Wall Street Journal

At the White Castle in Indiana, Flippy handles not just fries but most of the restaurant’s side items, including cheese sticks and onion rings. That means the humans who work alongside it have more time to interact with customers, says Mr. Richardson. “If you know you’ve got the fryer covered, it frees you up to have the right person taking orders in the dining room, or the drive-through,” he adds.

Automation has always promised more efficiency, says Dr. Cowan, but in her research she has found that, just as often as it decreases the labor required, it also raises the bar for the quality and variety of goods consumers expect.

Today, in other words, kitchen automation is being viewed as a way for restaurants, ghost kitchens and delivery giants to save time and money. In the future, however, it might be just another way to compete for the attention of the ever-fickle consumer—leaving the amount of human labor required

more or less the same

.

“In 1921, we had four menu items—hamburgers, Coca-Cola, coffee and apple pie, but as time goes on, people want more variety,” says Mr. Richardson of White Castle. The kitchen of the future, he adds, is one more way to provide it.

For more WSJ Technology analysis, reviews, advice and headlines,

sign up for our weekly newsletter

.

Write to

Christopher Mims at

christopher.mims@wsj.com

Copyright ©2021 Dow Jones & Company, Inc. All Rights Reserved. 87990cbe856818d5eddac44c7b1cdeb8