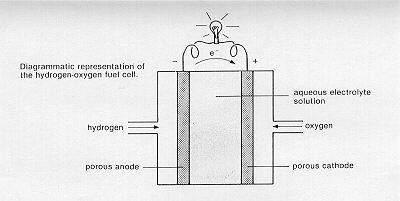

The simplest fuel cell “burns” hydrogen in a flameless chemical reaction to produce electricity. In order to ‘burn’ the hydrogen, a fuel cell needs a source of oxygen and this is usually obtained from air. The only by-product from this type of fuel cell is water.

Unlike a battery, a fuel cell does not store chemicals to produce energy. A fuel cell will produce electricity as long as fuel and oxygen are supplied.

The circuit in a simple fuel cell

A simple fuel cell consists of two conductors (an anode and a cathode) separated by an ionic conductor – an electrolyte – (eg, a salt solution). Hydrogen is pumped to the anode, and oxygen to the cathode. Hydrogen reacts with charged particles (ions) in the electrolyte, producing water and electrons. The electrons leave the fuel cell along wires; this is the electric current generated by the cell. The electrons return to the fuel cell cathode where they combine with oxygen and water to form ions which replace those consumed at the anode. And so the cycle continues, with hydrogen and oxygen being turned into water while generating electricity.

Simple fuel cells in space

Each simple fuel cell generates up to 1.23 volts. Individual cells can be wired together to produce greater voltages or higher current. The space shuttle, for example, has 96 individual cells arranged in three stacks. When hydrogen and oxygen are pumped into the shuttle’s fuel cells, they generate 28 volts of direct current as well as heat and water. The heat is put to good use, vaporising the liquid fuels before they reach the fuel cells. Water flows into storage containers for drinking and other uses.

Some different types of fuel cells

Fuel cells are based on a simple principle. However, the chemical reactions involved do not occur readily. Unless special materials are used to construct the cells, very little electric current is produced. Much of the research with commercial fuel cells has focused on the development of suitable electrolytes.

Phosphoric acid fuel cells, using acid as the electrolyte and fuelled by hydrogen gas, are the most commercially developed type of fuel cell. They are being used overseas in hospitals, nursing homes, hotels, offices and schools.

Molten carbonate fuel cells promise high efficiency and can be powered by coal-based fuels such as carbon monoxide instead of hydrogen gas. These cells must be run at high temperatures (around 650°C) because they have a carbonate electrolyte that must be kept in a liquid form.

An Australian company, Ceramic Fuel Cells Ltd, is commercially developing highly efficient solid-oxide fuel cells (also known as ceramic fuel cells). These cells, unlike their predecessors, have a solid electrolyte separating the two electrodes. The cells can be fuelled by a variety of gases, including hydrogen, natural gas or coal gas.

They promise to be very efficient. They operate at 800°C and the hot exhaust gases can be fed to a turbine, extracting even more electricity.

The solid electrolyte consists of an exceptionally tough ceramic membrane of zirconia. Zirconia, or zirconium oxide, is a compound of the metal zirconium. (Conveniently, 70 per cent of the world’s supply of this metal comes from Australia.) Heat the zirconia and you have a solid-state electrolyte able to rapidly transmit oxide ions from cathode to anode.

The trick in getting the oxide ions to migrate across the solid electrolyte is to add tiny amounts of the element yttrium, a silvery-grey metal, to the zirconia during manufacture. The crystalline array of zirconium oxide (ZrO2) has two oxide ions to every zirconium ion. But in yttrium oxide there are only 1.5 oxide ions to every yttrium ion. The result: gaps in the crystal structure where oxide ions are missing. So, oxide ions from the cathode leap from hole to hole until they reach the anode.

Once at the anode, the oxide ions readily react with whatever gaseous fuel they encounter – carbon monoxide, hydrogen or methane – liberating electricity.

Proton exchange membrane (PEM) fuel cells, also known as polymer electrolyte fuel cells, are the most promising technology for transport applications. Built from components of carbon and polymer and operating at 60-90°C, proton exchange membrane fuel cells are lightweight and allow fast start-up and shut-down. They are also very compact.