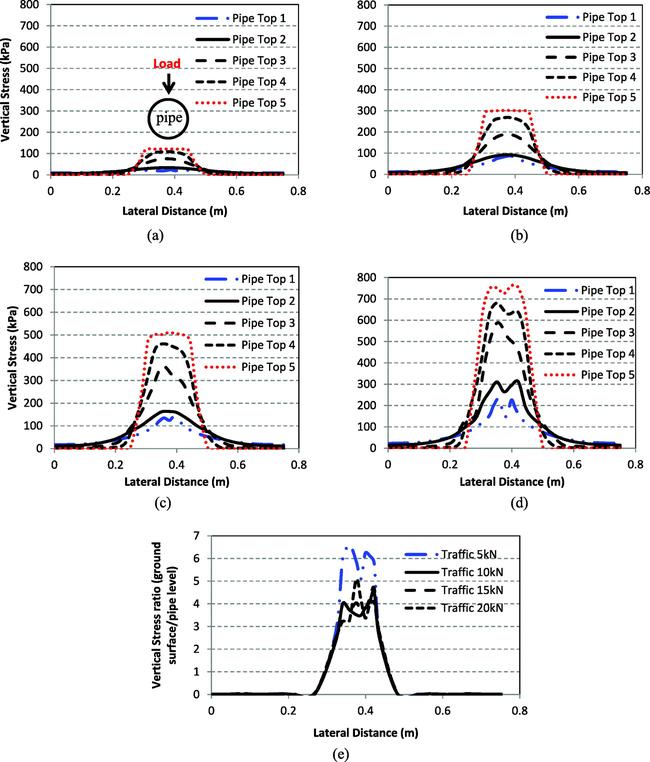

The article attempts to evaluate the comparison values of the culvert displacements and stresses made in four different technologies with the permissible standard values based on laboratory tests on a natural scale. Models were made using PE plastic and corrugated steel sheets. In this case, the results of the structural tests were compared under a failure load.

An example of damage caused by an overload of buried flexible structure is shown in Fig. 1.

The topic described in the paper is very important due to the fact that in recent years, research and analysis of culverts under various types of loads are still being carried out. This is related to both culverts in situ tests1,2,3,4, as well as numerical analysis of different load cases5,6,7,8,9.

In the case of buried flexible structures, the impact of the backfill on the soil-shell interaction is less pronounced than in the case of rigid structures. This is because in these structures, once the ground is made, a natural vault is formed in the backfill, limited from the top by the road surface and from the bottom by the curvature of the structure. This phenomenon is called "vaulting", although in the natural situation it occurs as a result of creating a hole inside the stabilized natural soil and not in the embankment of the soil-covered structure under construction10. In such a situation, the dead load of the layers (soil backfill and roadway substructure) and the live loads cause much less reaction on the foundation than in a rigid (classic) vaulted structure. In the case of buried flexible structures, the interaction of the flexible structure with the soil backfill is employed. Therefore the main load-bearing structure is the soil backfill as well as the reinforcing geotextiles. In the case of rigid culverts, the backfill is only the filling without significant interaction.

Despite the extensive theoretical research that has been carried out to model soil-structure interactions leading to many mathematical relationships and empirical equations, most of them present a shortcoming in considering the actual soil-shell-interaction response. One common way to obtain real information about this interaction is to develop a physical model capable of providing various conditions11,12. Such model allows the measurement of most parameters related to the behavior of the buried flexible structure with high accuracy. At the same time, the model allows, to measuring parameters under various service loads (static, dynamic and fatigue), and also to determine the mechanism of failure of such structures under an extreme live load. It is the most accurate method of performing such analyzes13, which can certainly be supplemented with the most modern FEM analyzes, including heterogeneous models of structure material14.

The article presents the results of analyzes of four full-size laboratory cases made in different technologies. In all cases, the applied loads exceeded the assumed standard loads by 400%. The studies provide a good basis for assessing the accuracy and reliability of the commonly used finite element analysis methods15,16.

It should be noted that compared to numerical analysis, building, testing, and then the demolition of the natural scale model requires a very large financial outlays. For this reason, such studies are conducted less frequently in the world.